| Min. Order: | 1 Set/Sets |

|---|

Basic Info

Certification: CE, ISO

Additional Info

Packaging: Export packing

Productivity: 300-350pcs/hour (4x8ft)

Brand: SHINE

Transportation: Ocean

Place of Origin: China

Supply Ability: 100 set per month

Certificate: CE ; ISO

HS Code: 8465960000

Port: Qingdao

Product Description

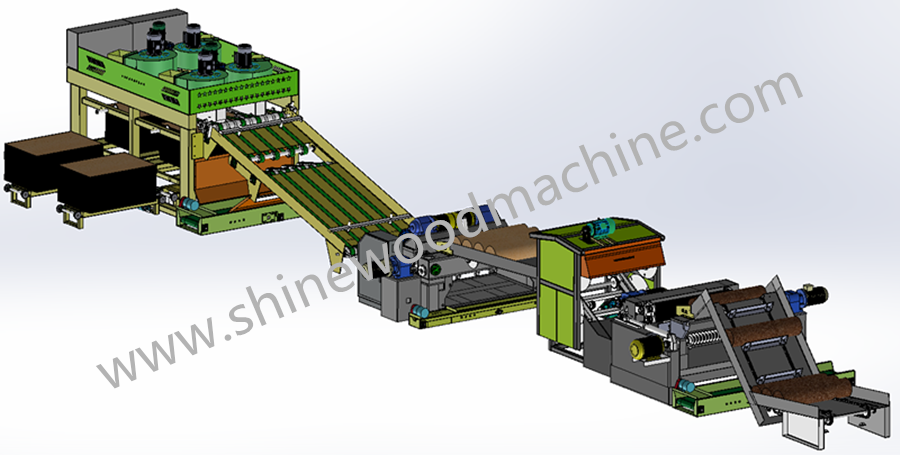

Plywood core veneer splicing machine is suitable for core veneer joining together in plywood production line. It can work different length sizes of core veneer with high strength thread and hot melt adhesive connection as one whole body Then facilitate the subsequent stages of production of plywood line. The whole process can be operated by one worker, it is time-saving and efficient. The whole process of the veneer splicing is as following : veneer feeding- material inspection-material selection-cutting plate-cloth glue-splicing-fixed length cutting-finished product -automatic stacking-auto launch. The veneer splicer machine is one section of the plywood production line . It mainly used together with veneer peeling line, veneer dryer , plywood hot press machine,plywood cold press machine and others .

Driver

All Servo Motor

Fuselage structure

Integral steel plate cutting

Conveying speed

0-35m/min

Capacity

300pcs/h

Working veneer width

968-1270 mm (3-4ft)

Cutting veneer length

1220-2560 mm (4ft, 5ft, 6ft, 7ft, 8ft)

Working veneer thickness

1.2-3.6 mm

PLC

Taiwan Delta

Output

300-350pcs/hour (4x8ft)

Weight

5500kg

Total power

16.5kw

1.PLC computer control, one-person operation, process automation save labor

2. High-precision detection, to minimize the amount of shear

3. Servo precise positioning, limited control overlap from the seam

4. Special high-strength wire, enhance product longitudinal tensile strength and flexibility is no longer broken1.

5. Use dedicated high-strength heat melts glue thread to stop the veneer breaking.

6. We use international famous brand parts such as Taiwan Delta, Germany Siemen

Roller core veneer dryer

Veneer peeling production line

© 2019 CHINA WAY. All Rights Reserved. Shandong Shine Machinery Co.,Ltd, Inc. All rights reserved. site map. sitemap.html